About C and C Tooling & Automation

Our Mission

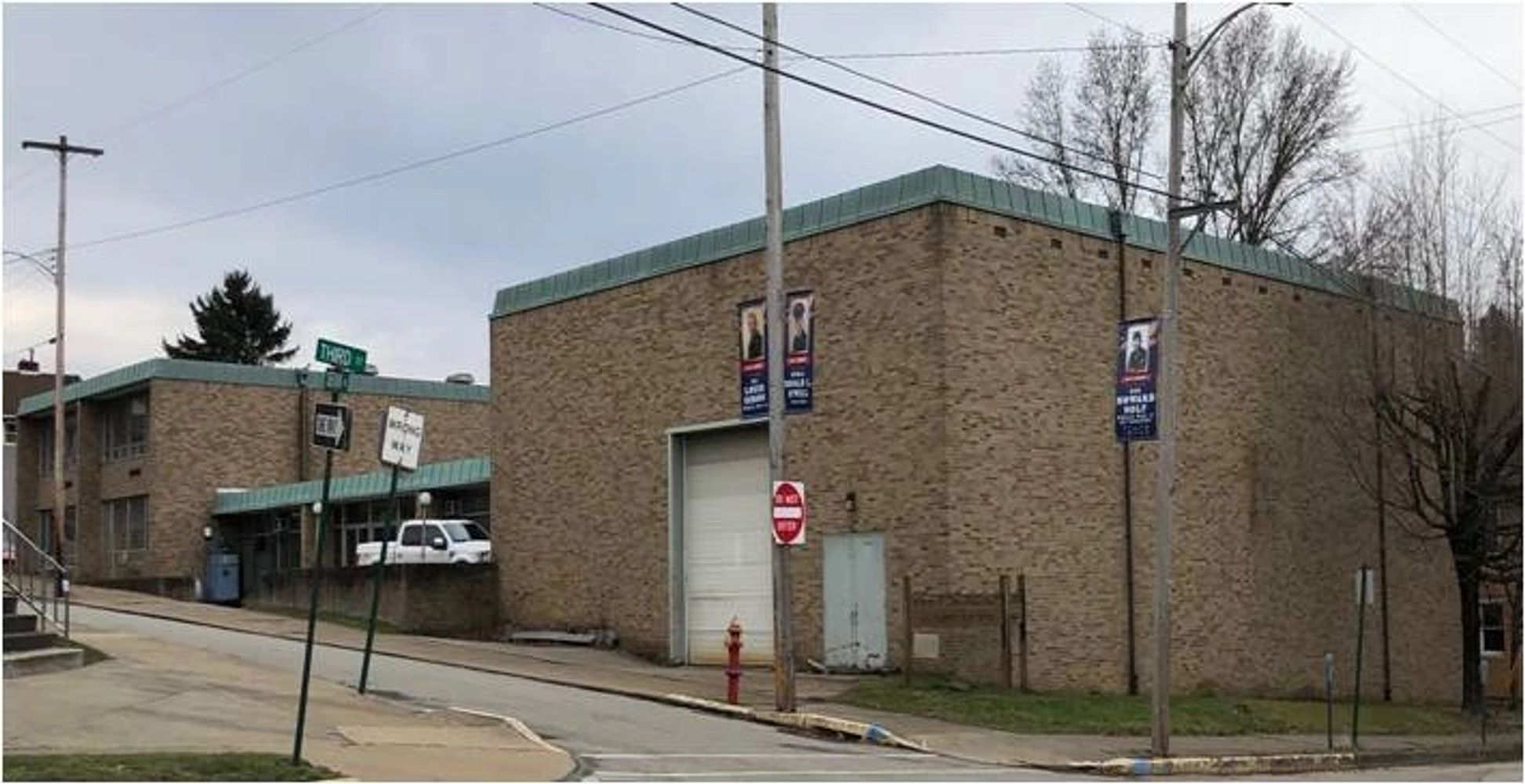

·Privately held company founded in 1996

·Located in Leechburg, PA

·22,500 Sq.ft floor space

·Our facility houses a complete CNC machine shop, welding and fabrication shop, assembly shop, and precision grinding and EDM services

Adapting to an always changing time, C&C Tooling has evolved from a tool and die business to an elite precision machine and fabrication facility. Built on the foundation of integrity and quality, our customer base has grown to include the Department of Defense, Automotive Industry, Oil and Gas Industry, and numerous others. We would like you to become another key company to our growing customer base. By using the most modern machines and equipment, we are always staying ahead of our competition. This also allows us to stay on the cutting edge of the manufacturing industry.

C&C Tooling, Inc

Consists of two groups – each supporting one another for customer requirements.

Tooling

Provides Precision Machining and fabrication services

Automation

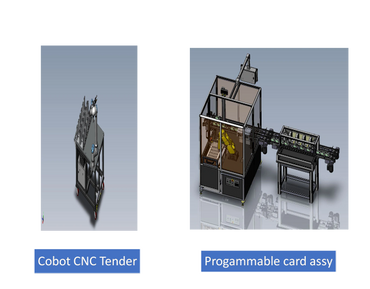

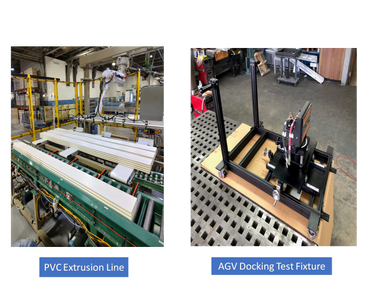

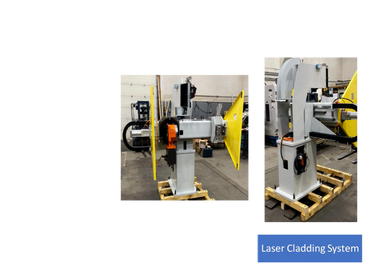

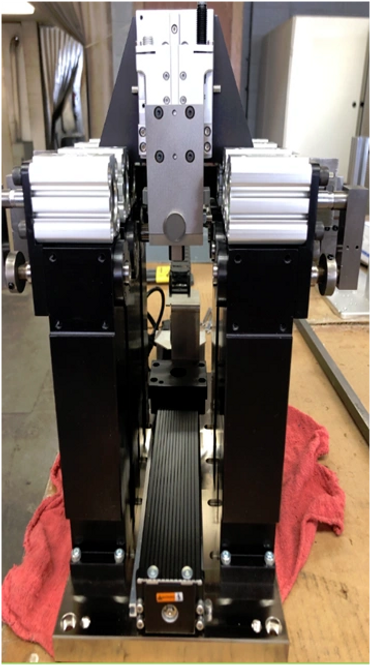

Creates custom-designed automated machinery and robotic work cells

CNC & Conventional Machining Equipment

·Mazak Super 2000L/120 §120” x 20” Travel·Mazak VTC-200B§20” x 40” Travel

·Mazak 414 (2)

§21” x 14” Travel

·Mazak QuickTurn 20H-P

§12” Dia. x 24”

·Bridgeport Machines (4)

·Conventional Lathes (2)

Precision Grinding Equipment

·Myford Cylindrical Grinder (2)

·Parker-Majestic Surface Grinder

Electrical Discharge Machining Equipment

·Agie Wire EDM

·Agie Conventional EDM

·Hurco Small Hole EDM

Fabrication Shop

·MIG

·TIG

·ARC

·Weld Certifications

·9ft x 14ft Siegmund Weld table with fixture tooling

Inspection Equipment

·(2) Coordinate Measuring Machines

·Gage Tooling & Indicators

·Surface Plates

·Optical Comparator

Core Machining/Fabrication Business

·Factory Automation

-Tool & Die

·Medical

·Consumer

·Oil/Gas Industry

·Medical

·Consumer

·Oil/Gas Industry

·R&D

·Prototyping

DOD Projects

Projects completed for the department of denfense

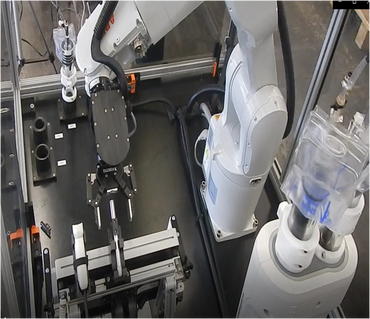

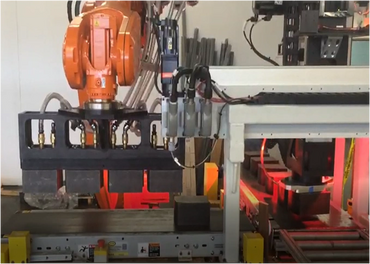

C&C Automation

·Our automation system specialists have a combined 80 years of service in the field of custom-designed industrial equipment and products.

·Experience is in all phases of solution development including: proposal creation, sales, contract negotiation, mechanical & electrical design, control programming, procurement, assembly, testing, installation and after-sales support.

Additional experience in management of engineering design teams across multiple disciplines and customer accounts to improve workflow and decrease time to market

Core Competencies

•Problem Solving •Mechanical Design •Project Management •Control Systems •Robot & PLC Programming •Web-based applications •Vendor Management •Proposal Development •Costing/Estimating •Analytical Thinking •Risk Assessments •Prototype Development •Multitasking •Client Relations •Scheduling •Pneumatics/Hydraulics •Electromechanical Systems •Robotic Workcells

• Machine Vision-Guided Robotics

•Synchronous and Non-synchronous Assembly Systems

•Bowl Feeding/Escapements •Bagging systems •Palletizing systems •Storage and Retrieval Systems

Design Development Tools

· SolidWorks

· ProEngineer

· AutoCad 2D&3D

· Microsoft Office

· Accurender

· Parts & Vendors

· Microsoft Project

· Robot Studio

· Solidworks PDM

Machine Vision Competencies

· Inspection/Measurement

· Guided Motion

· Barcode/UPC Recognition

· Color

· Feature Analysis

Control System Competencies

· PLC

· Robot (ABB, Fanuc, UR, Yamaha)

· DeviceNet

· PROFIBUS

· Ethernet IP, EtherCAT

· 1&2D Barcode

· Database Interface (SQL)

· Machine Safety Circuitry

· RF ID

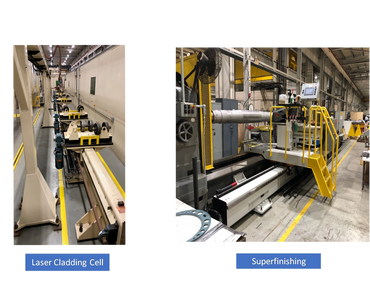

Installed systems

Partners

Contact Us

Better yet, see us in person!

We love our customers, so feel free to visit during normal business hours.

C and C Tooling & Automation

120 Siberian Ave, Leechburg, PA 15656, USA

724-845-0939 Clyde Ross- cctooling@windstream.net Chirs Ross- cross@candctooling.com David White- david.white@candctooling.com Chris Swank- cswank@candctooling.com

Hours

Open today | 09:00 am – 05:00 pm |

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.